HOME

RPS

Product Overview

Microwave RPS

(Remote Plasma System)

Sub-Fab. Safety Enhancement and by-product Removal System

-

- High References

- Specify range power (1~3KW )

- High usability (high output and various reactivity enables

reactions such as NF3 and O2, H2O)

Specification

| Content | Description | User Scope (HOOCK UP) |

|

|---|---|---|---|

| Model | TCTMW-R3 | ||

| Treatment type | Microwave Plasma | ||

| Application | Etch, Diffusion, CVD Process | ||

| Interface | RS485, Signal | ||

| Operation type | Automatic (PLC base TOUCH screen) | ||

| Dimension (W×D×H, mm) | 630×1,208×1,517 | ||

| Weight (kg) | 85kg | ||

| Power | 3-Phase, 220 ±10% VAC, 50/60㎐ Main Circuit Breaker / Max. Power Consumption / |

O | |

| InletPort | ISO 160 (Or Option) | ||

| Ar | 2 LPM | 1/4” VCR Male | O |

| NF3 | 3 LPM | 1/4” VCR Male | O |

| PCW | 20~30 LPM (4~5 kg/cm2) | 3/8”, Swagelok | O |

| Ar | 30~200 LPM (4~5 kg/cm2) | 1/4”, Swagelok | O |

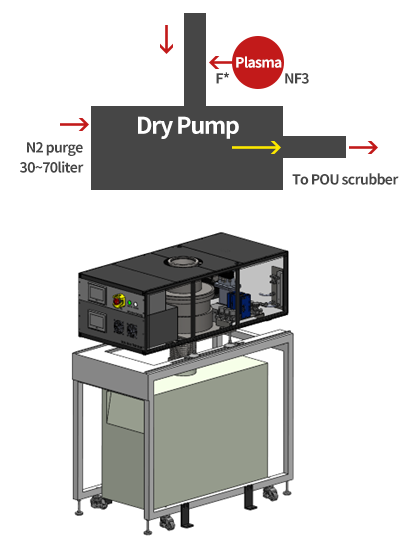

Gas processing process

Sub-Fab. Safety Enhancement and by-product Removal System

-

- WN process : By-Product W or WN

W or WN + F* → WFx + N2 - HARP USG process : by-product SiO2

SiO2 + F* → SiFx + O2 - ALD CVD Nitride : By-Product Si(NH2)4 or Si3N4

Si(NH2)4 or Si3N4 + F* → SiF4 (g) + NH4F2 (s) - ALD TiCl4 TiN : By-Product TiN

TiCl4 + NH3 + F*/O*+ NF*→ TiF4(s) + NH4F(g) + TiO2 (s)+ N2 + HCl(g) - ALD ZrO2 : CpZr or TEMAZ condensation(Safety issue)

CpZr[(N(CH3)2)3] + O* → ZrO2 + N2 + H2 + CO2 + H2O

- WN process : By-Product W or WN