Technology

Dry Scrubber

Dry Scrubber

Product Overview

-

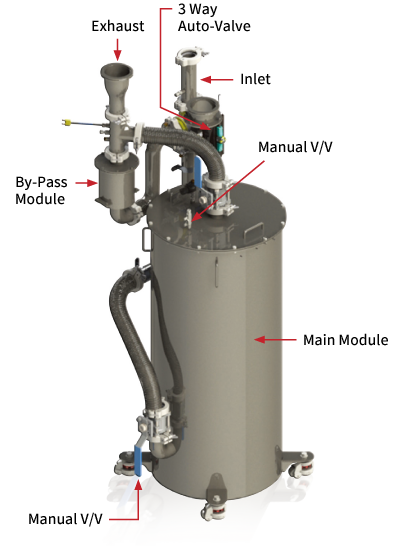

1Emergency Back-Up

- >> Unnecessary to down Main Tool During Change the Main Module

-

2By-Pass Module

- • Used gases released into the By-Pass line are passed through the By-Pass Module.

- • It is processed safely for more than 1 day.

-

33 Way Auto-Valve

- • Change to automatic backup mode when already set pressure valve is reached.

Advantage

-

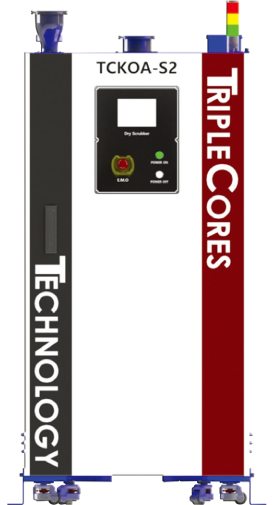

1Touch Screen : Push P.M Mode

-

2N2 Purge : 10min Over (Eliminate remalining Toxic gases)

-

3Close the Manual Valve

-

4Unlock the Clamp

-

5Take Out the Main Module

-

6Replace with a prepared (Include adsorbent in the Main Module)

-

7Prevent Powder and Corrosion

All Safety Devices must be met to operate.

There are safety devices to prevent Gas Leakage, Fire and Explosion.

- Regular P.M

- MTTR

(Mean Time To Repair) - Under 2 Hours

- 7 Steps

Safety

Device

Application

| Process | Gas |

|---|---|

| IMP | PH3,ASH3,BF3 |

| Chemical | HF,Cl2,NH3..(Acid, Alkali) |

Specification

| Content | Description |

|---|---|

| Model | TCKOA-S2 |

| Treatment type | Adsorbent |

| Application | IMP, Chemical (Acid, Alkali) |

| Capacity | ~200LPM (Customize) |

| Operation type | Automatic (PLC base TOUCH screen) |

| Dimension (W×D×H, mm) | Scrubber 800×800×1,610 |

| Weight (kg) | 400kg |

| Power | 1-Phase, 208Vac., 50/60Hz Max. consumption Power / 800 W |

Utility

| Content | Description | ||

|---|---|---|---|

| Specification | Connection | ||

| Inlet | 2~4 Port | NW50 KF | |

| N2 | 5~10 LPM (4~5kg/cm2) | 3/8", Swagelok | |

| Exhaust | Gas Exhaust | -40 ~ -80mmH2O | NW 100 MF Flange |

| Thermal Exhaust | -40 ~ -80mmH2O | NW 100 MF Flange | |