Technology

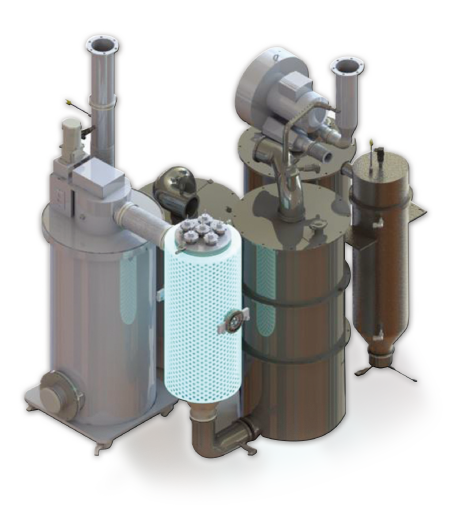

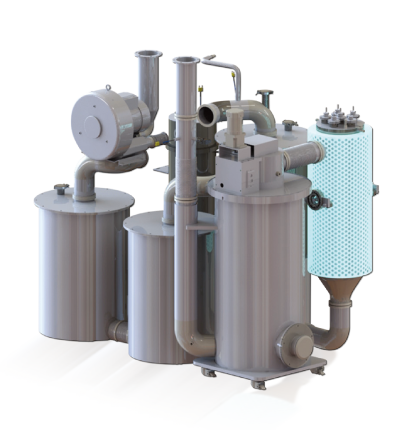

DeNox Scrubber

DeNox Scrubber

Product Overview

-

1Flow Sequence

-

Pre-treatment

Remove Powder -

Reaction

Remove NOx & NH3 -

After-Treatment

Remove Acid gas(HF) Decrease Temp. for Satety

-

Total : 5 Step > Remove NOx & By-Product Continuous Operation with Mutual Backup

| Contents | Selective Catalytic Reduction (SCR) |

|---|---|

| Theory | Convert NO to N2 by reaction of NH3 in the presence of catalyst |

| Additive gas | NH3 (gas) or NH4OH Solution |

| Reaction Temperature | 200 ~ 400℃ |

Advantage

-

1Catalytic Reduction of NO by using NH3 as a Reductant

-

2Continuous Operation with Backup Function

-

3NOx Removal Efficiency : Over 95%

-

4Small Footprint

-

5Treat Various Gases into One System

Application

| Process | Gas |

|---|---|

| NOx | NO, N2O, NOx |

| Mixed Gas | HF, Cl2, SiH4, VOC, NH3 |

Specification

| Content | Description |

|---|---|

| Model | DNS-4X |

| Treatment type | Adsorbent & Catalyst |

| Application | NOx, Mixed gas (Acid , NOx, VOC,NH3…) |

| Capacity | ~4,000LPM (Customize) |

| Operation type | Automatic (PLC base TOUCH screen) |

| Dimension (W×D×H, mm) | 1,700×1,700×1,800 |

| Weight (kg) | 1,800kg |

| Power | 3-Phase, 208Vac., 50/60Hz Max. consumption Power / 25KW |

Utility

| Content | Description | ||

|---|---|---|---|

| Specification | Connection | ||

| Inlet | 1 Port | NW100 KF FLANGE | |

| PCW | 30~200 LPM (4~5kg/cm2) | 3/8", Swagelok | |

| N2 | 100~200 LPM (3~5 kg/cm2) | 3/8", Swagelok | |

| NH4OH | 1~2(1~2 kg/cm2) | PTFE | |

| Exhaust | Gas Exhaust | -40 ~ -80mmH2O | NW100 MF Flange |

| Thermal Exhaust | -40 ~ -80mmH2O | NW100 MF Flange | |